- #Iso 4406 particle count chart Patch#

- #Iso 4406 particle count chart code#

- #Iso 4406 particle count chart iso#

Each number represents a contaminant level code for the correlating particle size.

#Iso 4406 particle count chart iso#

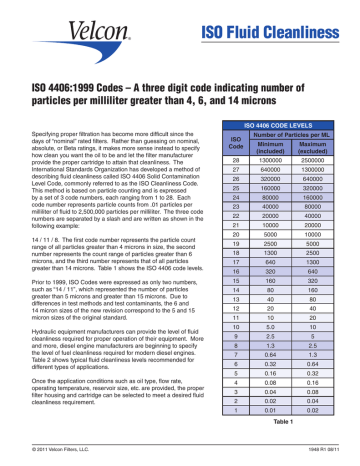

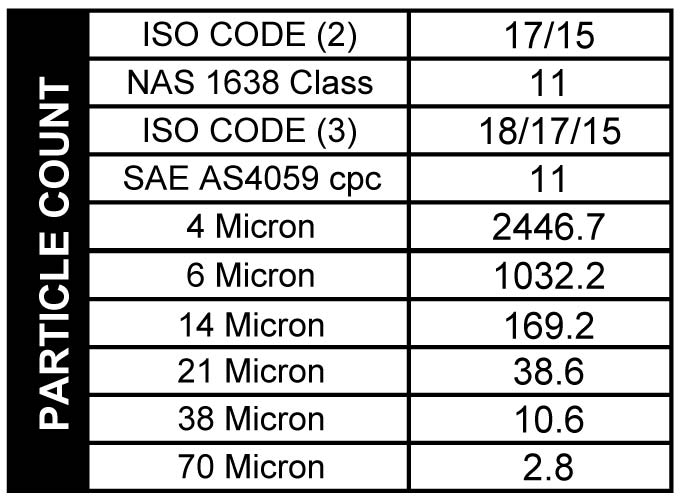

This ISO code is expressed in 3 numbers: 19/17/14. Using these tables we can get the recommended ISO cleanliness level for our system. The International Organization for Standardization created the cleanliness code 4406:1999 to quantify particulate contamination levels per milliliter of fluid at three sizes: 4 c, 6 c, and 14 c. There are generic recommendations of cleanliness class, The cleanliness level required in lubricating and hydraulic systems is determined by the most sensitive component. These tests results are good examples why it necessary to do: Knowing what contamination levels can be expected in a given application -and carrying out a proper interpretation of the oil analysis - is the key to understanding the effects of oil contamination. There is very important to clean even brand new oil before fill the hydraulic tank. There are approximate comparison tables for other standards, To determine the cleanliness level by ISO 4406/1999 the solid particles present in 100 ml fluid are counted, sorted according to size & quantity and classified into particle ranges, defined by two (Microscopic counting) or three (automatic particle counter) numbers divided by slashes: To determine the cleanliness level by ISO 4406/1999 the solid particles present in 100 ml fluid are counted, sorted according to size & quantity and classified into particle ranges, defined by two (Microscopic counting) or three (automatic particle counter) numbers divided by slashes: There is very important to clean even brand new oil before. There are a lot of different standards for the classification of solid particle contamination in lubrication and hydraulic fluids: ISO 4406/1999, NAS 1638, SAE AS4059, GOST 17216-2001, etc. Recommendations for Locations of Filters at your system.2018 17 22 00 gmt ccna images and features boson com. This approach streamlines the monitoring of. understanding iso cleanliness codes january 2011. By placing a liquid particle counter in-line with an ICP-OES system it is possible to analyze wear metals and particles in lubricant samples in one run.

guide to contamination standards parkerhfde.

#Iso 4406 particle count chart Patch#

0 kommentar(er)

0 kommentar(er)